1. Introduction

Already in the 1960’s Tony Wrigley pointed out that the industrial revolution could be analyzed in

terms of changes in the way society was organizing its energy flows (Wrigley,

1962). Prior to the industrial revolution, energy flows were based on

photosynthesis, a system Wrigley labelled the organic economy. As the capacity

to produce energy in the form of foodstuffs, fodder and firewood through

photosynthesis was ultimately limited by the acreage available for forest and

agriculture, the potential for achieving economic growth was limited in the

organic economy, an argument that rests on the assumption that energy is

complementary to man-made capital. Coal did not experience the same limitations

on the size of the energy flows and therefore allowed economic growth. The

emergence of modern, high and sustained economic growth rates were therefore

closely associated with the succession from an organic to a mineral-based

economy. More recent empirical work has analysed energy transitions in several

countries based on quantitative estimates of the development of various forms

of primary energy such as firewood, coal and oil. The works of Tony Wrigley

(1988, 2010, 2016), Richard Wilkinson (1988), Peter Sieferle (2001), Kenneth

Pomeranz (2000) and even Bob Allen (2009) aims at understanding the industrial

revolution and they all, in different ways, recognize the role of energy in

this transformation. Another line of research has aimed at reconstructing

historical energy data in foremost physical units, elaborating measures such as

the energy intensity of GDP (Gales et al., 2007; Kander, Malanima & Warde, 2013; Lindmark & Minde, 2018).

The ambition of this article is to present an analysis of the Swedish

industrialization from an energy historical perspective, with the aim to

uncover dynamic relationships between economic and energy transformation. Our

main argument is that the Swedish industrialization process was shaped by the

co-evolution of organic and mineral systems and these dynamics, in turn, were

shaped by the industrialization process itself. We attempt to use a holistic

view, deliberately avoiding to focus on the energy system itself, while arguing

that the energy transition also interacted with institutional changes,

entrepreneurial activity and technological change that affected demand for

fuels and raw-materials through changing relative prices.

Early modern Sweden enjoyed vast per capita forest and hydropower resources

which, however, could not be fully realized due to relatively poor agricultural

conditions. Interestingly enough, the plentiful per capita forest and hydro

resources mirrored a low population density. Due to its fair supply of firewood

and hydropower, Sweden appears as a relatively blessed country during the

pre-industrialized era as far as energy resources are concerned. With the

exception of the southernmost parts of the country, forest was a dominant

feature of the landscape. Inland Norrland, a significant part of the country’s land area, was to an even higher degree dominated by woodlands. Yet, many of

these resources were largely inaccessible for economic exploitation of any

significant scale. The organic energy resources of a good part of the country’s area were therefore not assets in an economic sense. As we try to argue in the

article, this was a consequence of the organic energy system itself. The

paradox is that the organic energy system limited the access to organic

resources.

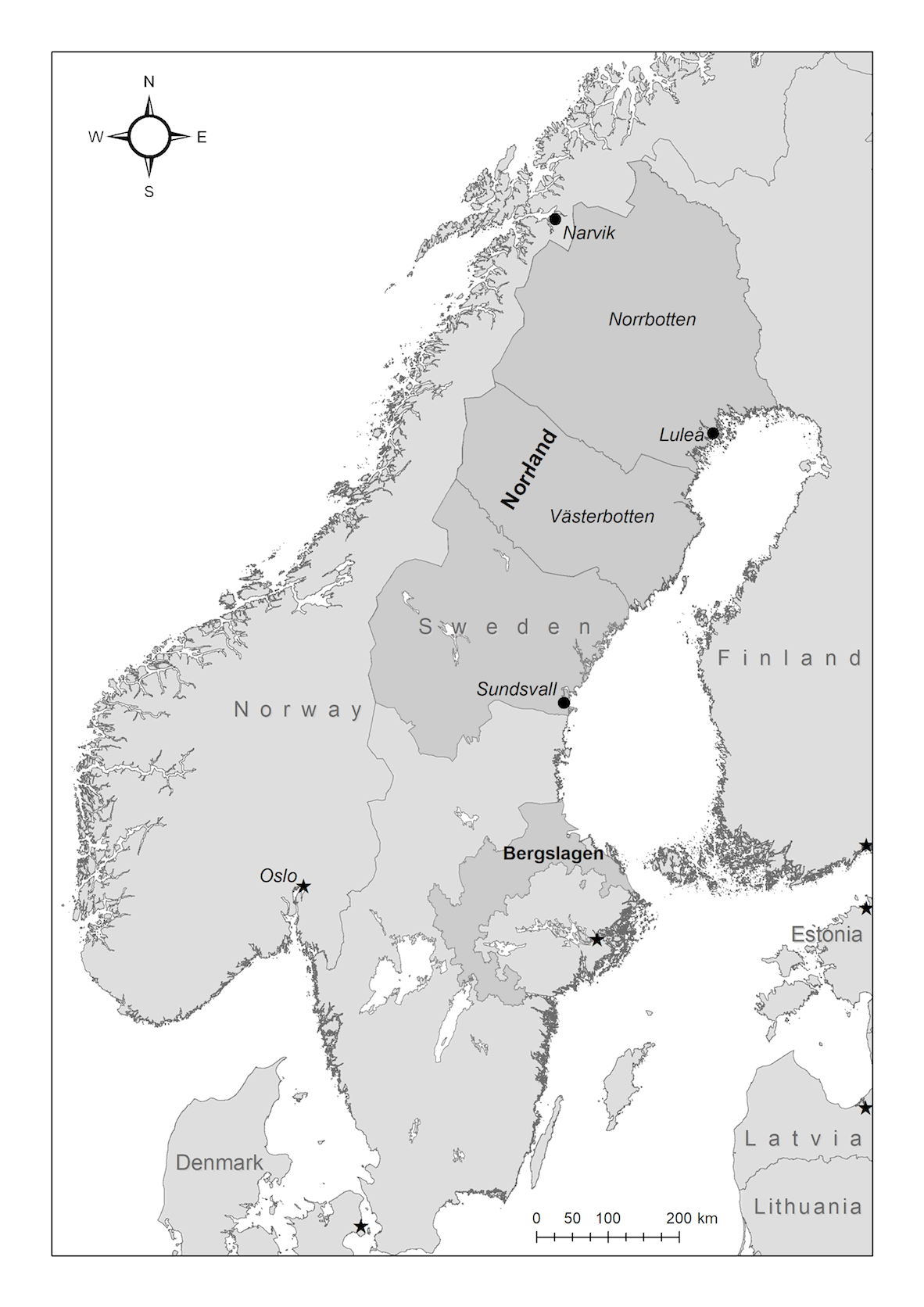

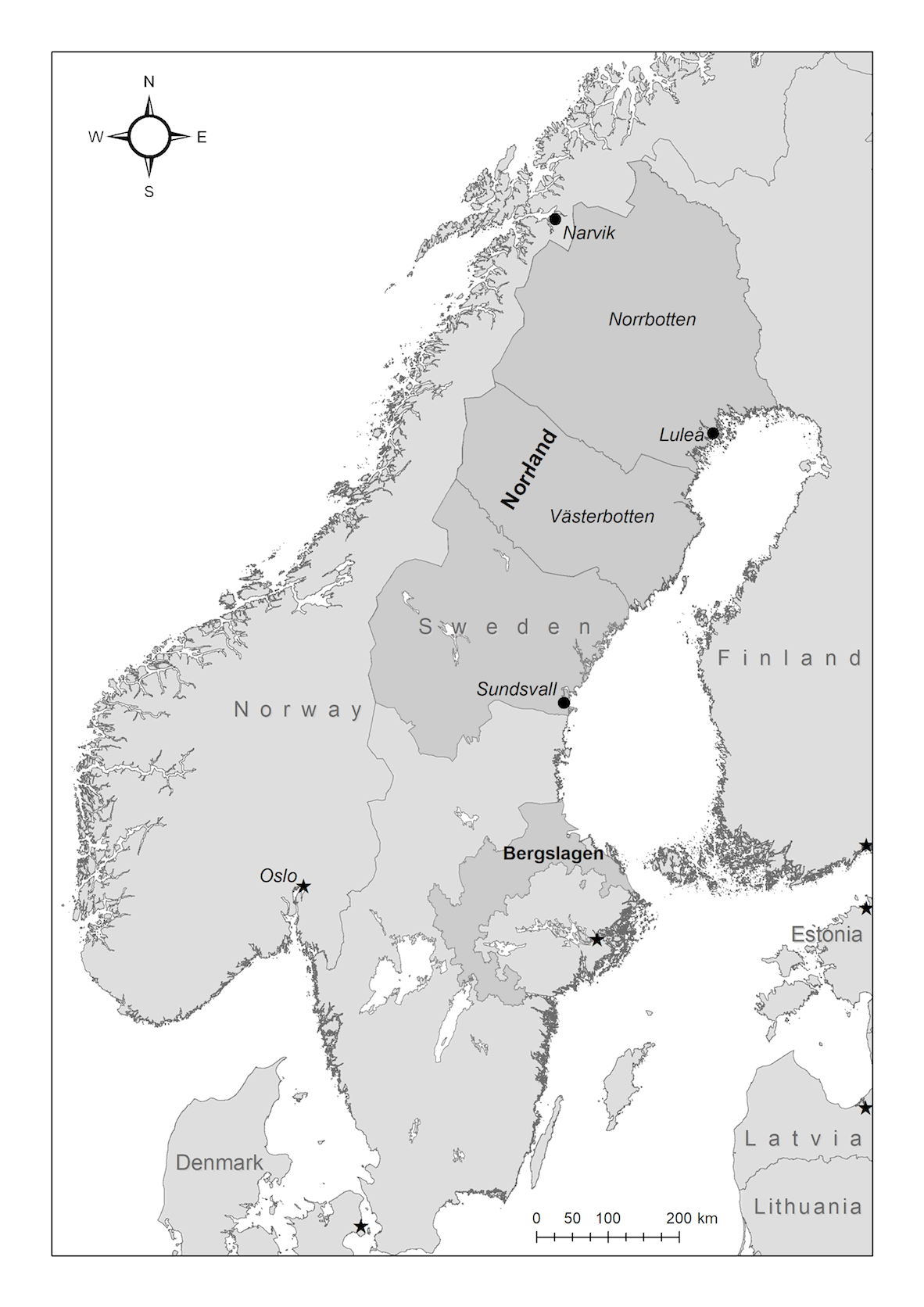

Map 1

Area of research

Around three quarters of the Swedish land area is found in the boreal coniferous

forest, or taiga. A short growing season meant that the supply of productive

agricultural land was limited in comparison to 3 European countries. The

exception was the southern parts of Sweden, with agricultural conditions more

similar to Denmark or Germany. We also notice evidence of agricultural

surpluses in the Stockholm Mälardal region from the 17th century (Myrdal, 1999). Generally, however, inadequate farming conditions,

mainly determined by the country’s northern location, explain the low population density compared to central

Europe. The flip side of the low population density was, however, a large stock

of non-agricultural assets in the form of forests and hydropower. Additionally,

Sweden was endowed with significant mineral resources, with known deposits of

iron and copper ores in the mid-central districts known as Bergslagen.

As the conditions for agriculture in these districts were not fully

satisfactory, but since parts of the surpluses in the Mälardal region could be used for supporting miners and iron workers, there was

enough manpower for the development of an iron and copper industry (Jonsson,

2001: 89-91) In short, the early modern iron industry benefited from a

favorable factor endowment of mineral resources, hydropower, decent

agricultural conditions and adjacent boreal forests for charcoaling. It was,

however, difficult or even nearly impossible to utilize the resources of

northern Sweden before the industrialization itself.

2. Northern Sweden and its factors of production

The fact that factor endowments frame the energy transition from an organic to a

mineral energy was evident in the case northern Sweden. In this part of the

country there were large areas of more or less unexploited forests, especially

old-grown spruce with high-quality, dense timber which was due to the slow rate

of growth in the harsh climate. When Carl von Linneus undertook his expedition

to Lapland in 1732, he noted the economic potential of the forests, but also

pointed out that the trees stood there, in vain and to no benefit. (Linnaeus, 1960). The timber did not have any commercial economic value.

Linnaeus argued that if only the right spirit was there to cultivate the

forest, there were enormous riches to be gained. While the continental powers

fought over overseas colonies, Sweden had a colony within its own borders. The

idea of an internal colonization was not at all new in the 1700s (Sörlin, 1988: 24). Sverker Sörlin points out that Olaus Magnus already in 1555 cited old authorities giving

voice to the same idea. Northern Sweden had several small coastal towns that

had been established in the Middle Ages, while the area was indeed populated

before the Swedish Crown had put the coast under its jurisdiction. For long,

historians have tried to understand who these first settler were, including

speculation over the true identity of the mysterious Kvaener as well as the

emergence of the Birkarlar in the 14th century (Harrisson, 2002: 741-50). The latter may have been a then new word for

the indigenous non-Sami population who earned their living in a combination of

agriculture, fishing, hunting and trade, and who, after the area was put under

the jurisdiction of the Swedish crown in the 14th century, also came to function as state officials and tax collectors. Northern

Sweden, not the least the interior parts, was also populated by the Sami

people, with an economy based on reindeer nomadism, fishing, hunting and trade.

The settlements in the interior were during the 1600s very small, obviously a

reflection of the harsh climate, most notably a short growing season with a

persistent risk of crop failure. Basically, proper farms were found along the

river valleys in the coastal area, while the inland favoured hunting. From a

biological perspective, northern Swedish agriculture was highly dependent on

dairy farming, since the short but intense growing season was relatively most

favorable for grass (Gadd, 2000). The Sami reindeer herding utilized

non-cultivated fodder, lichens, in areas were agriculture was practically

impossible. The forest was used for domestic building material and fire wood,

but not for commercial purposes of any important degree. An important factor

explaining why the forests were not used for commercial purposes was the low

population density and, therefore, an inadequate labor supply.

The existence of huge iron ore deposits in the northern parts of the country

were known from 16421 (Norberg, 1958). Regrettably, the majority of these deposits had a too high

phosphorous content to be utilized with contemporary technology. Sufficiently

large low-phosphorous deposits had, however, been discovered for advancing an

industrial exploitation, a project which faced at least two major challenges.

Firstly, the population in northern Lapland was even smaller than in other

parts of Norrland and, secondly, the forest supply was limited at best. This

meant that the ores of Norrland were inaccessible implying that the only

remaining solution was to transport iron ores to the ironworks that had been

established along the coast. The transport network, depending on rain deer

sledge transports during the winter was, however, not successful, due to low

economies of scale. It is furthermore important to recognize that the main

reason for allocating iron works along the Norrland coast was to counteract the

fuel shortages in the central Swedish iron districts. Due to the problems

related to transportation and extraction, the ores for the Norrland ironworks

were shipped from the Stockholm archipelago. The vision of a large-scale

colonization of inland Norrland, exploiting forest and mineral resources, was

however not possible until a sufficiently large population could be

established. Basically, this could not happen before the interior Norrland was

integrated in the growing national and international economy, something that

only happened decades after the Industrial Revolution. Before we attempt a more

holistic interpretation of the Swedish energy transition and industrialization,

it is, however, necessary to look more closely into how the hallmark technology

of the industrialization, the steam engine, diffused into Sweden, thereby

significantly linking the Swedish economy to the mineral energy system.

3. Sweden on Steam

The Dannemora mine steam engine project of 1728 exemplifies how factor

endowments, including not only energy but also technical know-how and real

capital, determined how technologies of the industrial revolution and the

mineral energy system could be applied in Sweden (Lindqvist, 1984). Already a

decade after Newcomen had assembled his first steam engines in England, the

powerful Swedish Royal Board of Mining decided to evaluate the technology. The

basic challenge that the Board wanted to address was, as in England, flooding

of the mines due to hydrological conditions. After the plans on evaluating a

steam engine had first surfaced in 1715, just three years after Newcomen’s first engine, a so called fire and air machine was built in the Dannemora iron ore mine in 1728, under the auspices of the

Swedish engineer Mårten Triewald. Unfortunately, it turned out that the machine consumed excessive

quantities of firewood. Since the wood had an alternative use as charcoal for

use in the nearby blast furnaces, foundries and forges, the opportunity cost

was high. This marks a striking difference to the British case, where the steam

engines were set up at the mouth of the coal pit where the fuel cost was close

to nothing. In Sweden, however, the costly fuel consumption meant that the

machine was not profitable, which in turn deterred the Royal Board of Mining

from resolving the remaining technical problems which, among other things,

included that it did not operate well under winter conditions. The production

factor missing at Dannemora was coal. Know-how, including engineering skills

and information on the British developments, was clearly present. The

institutional framework was also sufficiently well-functioning for encouraging

the investment in the first place but also to scrap the project when profits

were not realized2.

The first steps towards a transition to a mineral energy system in Sweden came

with the Watt steam engine and the British engineer Samuel Owen, a Leeds based

engineer who moved to Stockholm in 1804 on initiative from his Swedish business

contacts, who had previously bought British steam engines for two breweries,

one textile industry and one flour mill (Sundström, 2009). Bob Allen’s point that the technologies of the industrial revolution could not be diffused

until their designs had been sufficiently refined (Allen, 2009) therefore seems

to be justified also in the Swedish case. In Stockholm, Owen constructed his

first steam engines for industrial use, as well as small steamers such as the

Witch of Stockholm. Not without reason it is often considered that Owen played

an important role in the establishment of a modern engineering industry in

Sweden as several spin-offs such as Boliders (nowadays part of Volvo) and Atlas

Copco were started by his apprentices. Owen’s business operations may, from an organizational perspective, be seen as part

of the transition from the biological to the mineral-based energy system in

Sweden, and shows on the micro level how individual actors and entrepreneurs

played a role in the transition. In essence, Owen, and his Swedish business

partners, transferred critical know-how from Britain to Sweden. It is

furthermore likely, although it remains a future research issue to fully prove

the point, that the fuel demand derived from the increased used of steam

engines was a crucial driver behind the early diffusion of the mineral energy

system to Sweden.

4. The origins of the demand for coal

As railways directly contributed to an increased demand for coal, the national

railway project, with the first trunk line completed in 1856, was one of the

main drivers behind the Swedish energy transition. The reason why railways were

so important for propelling the transition was that railways did not run well

on firewood. The locomotives, originally of British or German designs, were

intended to run on coal. As a matter of fact, coal hold much better qualities

for steam engines as compared to biofuels such as wood or peat. This is

especially so concerning locomotives, with high demands on power and limited

size. Here lies some important, but often overlooked technical circumstances

which are important to consider. First, coal has a significantly higher energy

content in relation to its weight than biofuels. If volume is instead

considered, which is some respects is more important than weight, the

difference becomes even more striking. One cubic meter of wood is in energy

terms equivalent to approximately 0.17 tons of coal. As the density of coal is

about twice as that of wood, this means that one cubic meter of coal weighs

around two tons, which in energy terms corresponds to around 10 cubic meters of

wood. A steam locomotive such as model SJ Litt. B., a Swedish design from 1909,

had a fender with a coal storage capacity of 6 tons, corresponding to around 35

cubic meters of wood. Furthermore, as locomotives need to develop significant

amounts of power, there is a close relationship between locomotive power and

the boiler capacity, measured in tons of steam per hour. One important factor

affecting the boiler capacity is the rate at which the fuel can be burned,

which gives how much energy that can be transferred to the water in the boiler

per hour. Since the area available for burning fuel is limited in a locomotive,

attempting to run a locomotive on firewood reduces the boiler capacity and thus

the locomotive power by approximately 50%. Coal was also the preferred fuel for

stationary industrial steam engines, even though it is possible to keep up the

boiler capacity by simply constructing a large boiler and extending the

combustion area. Even in this case, a larger boiler would be needed if biofuels

were used. Adding to these disadvantages of biofuels, peat and even fire wood

also contain some amount of water, which means that energy is spent on drying

the fuel itself3.

FIGURE 1

Swedish coal imports by sector of destination, 1800-1913

Source: Lindmark and Olsson-Spjut (2018).

In quantitative terms, and as shown in Figure 1, Swedish coal consumption,

almost entirely based on imports, began to increase from 1840. Lindmark and

Olsson-Spjut have shown that the rise can largely be explained by the

increasing steam motive power in the industry, the development of steamship

tonnage, the recorded railway fuel consumption and the coal consumption in

gasworks (Lindmark & Olsson-Spjut, 2018).

Other sectors, including domestic heating and heating of other premises,

constituted a smaller, while not insignificant share of the coal consumption in

Sweden. Lindmark and Olsson-Spjut (2018) therefore suggested that the

increasing demand for coal during the second half of the 19th century was derived from the mechanization of the leading economic sectors

during the industrialization. Still, the Swedish energy transition was

characterized by a dynamic interaction between the organic energy system and

the mineral system, which created synergies between both systems. The expansion

of the saw mill industry along the Norrland coast initially utilized mechanical

hydropower. Steam power, a technology of the mineral system, grew in importance

from the 1850’s, especially because steam made it possible to locate the mills to more

favorable coastal locations. Still, the saw mill industry could utilize

sawdust, a biofuel of the organic energy system, as a main fuel for the steam

engines. Such synergies are distinguishing features of the Swedish energy

history during the 19th and well into the 20th century. Before we devote further attention to the manufacturing industry we

should look at the energy transition from the rural point of view.

5. Firewood in the domestic sector

During most of the 19th century, the Swedish primary energy consumption was dominated by fire wood for

domestic uses (Kander, 2002). Domestic heating and cooking technologies saw

significant improvements during this period, including the tile stoves and,

later, the iron stoves, which from the perspective of energy transitions begs

the questions whether these heating technologies saved on fire wood to such

extent that alternative uses of the forest resources, not the least as basic

raw material in the saw mill industry, could be realized. If so,

transformations within the organic energy system, may have played an important

role in the Swedish industrialization.

The historical sources on household firewood consumption are unfortunately

sparse and rather unreliable as far as the 19th century is concerned. We can therefore only make informed guesses about the

developments of fire wood consumption prior to the more reliable investigations

from the 1920s. What we know is that the bulk of the fuel consumption occurred

on the countryside and that the urban fuel consumption, also when counted per

capita, was significantly lower due to overcrowding and a more frequent use of

tile stoves. Urbanization therefore tended to reduce per capita energy

consumption. Both the iron stove and the tile stove were innovations with a

higher thermal efficiency than traditional fireplaces, but wether the new types

of stoves actually reduced per capita firewood consumption in rural areas is

not known with certainty. The dilemma is to what degree improved heating

efficiency was used for reduced firewood consumption or higher indoor

temperatures in combination with an increased number of heated rooms4. It is also uncertain how the growth of the landless rural working class in the

1800’s, living in smaller crofts rather than farms, affected the aggregated fuel

consumption. If one, as a counterfactual thought experiment, assumes that the

domestic per capita firewood consumption was the same in early the 19th century as it was in the 1920’s, one arrives at a consumption around 5 million cubic meters of fire wood in

1800. This roughly corresponds to the forest industry’s consumption of saw timber in the mid-1860s. If, on the other hand, the effects

of improved spacing heating technologies were strong, assuming that the per

capita consumption halved between 1800 and 1920, the household firewood

consumption would have been around 10 million cubic meters in the early 19th century, equivalent to the forest industry’s raw material consumption around 1890 (Lundgren, 1984). If so, the energy

savings within the household sector would literally have saved significant

amounts of firewood.

The forest industry was a key sector in the Swedish industrialization process

and the saw mill industry timber consumption rose from one million cubic meters

in 1840 to 11 million cubic meters in the 1890s (Lundgren, 1984: 223-25).

During the same period the total fire wood and charcoal consumption in other

manufacturing sectors probably increased from approximately 4.7 million cubic

meters to 6.5 million cubic meters of wood (Lindmark & Olsson-Spjut, 2018). The output growth, measured as the industrial value added

volume, increased sevenfold from 30 million to over 225 million 1913 SEK over

the same period (Krantz & Schön, 2007). This demonstrates a sizeable gain in terms of firewood efficiency

during the initial phase of Swedish industrialization, which was mainly driven

by a more efficient use of charcoal in the iron industry. Coal substituting for

firewood or charcoal was hardly important for the developments at the

aggregated level during the 19th century as the Swedish iron industry, by far the largest industrial consumer of

fuels, largely remained on charcoal until after the First World War.

The vast forest resources in interior northern Sweden were first utilized on

commercial scale from approximately 1850. This geographical expansion of the

forest industry, known as the timber frontier, originated in the Oslo area in

the 1700s. By the 1840’s, the frontier had reached the city of Sundsvall and twenty years later

northern Västerbotten to, finally, reach Norrbotten by the mid-1870’s (Bunte, Gaunitz & Borgegård, 1982: 135). An important driver was the demand for large, old grown timber

which became increasingly scarce as the saw mill operations expanded. The

timber frontier coincided both with a transformation of the agriculture in

interior Norrland and with the development of a distribution system of

foodstuffs from southern Sweden to the north and further inland. It is

important to recognize that the inland agriculture operated at the geographical

edge of farming. The famines of 1867, 1868 and 1869 had demonstrated how

sensitive the northern agriculture was to crop failures and how food transports

were disrupted when harbours froze over earlier than expected. When analyzing

the expansion of logging operations it is important to recognize that the

inland agriculture hardly produced any surpluses. Dan Bäcklund stated that the inland Norrbotten farms before 1870 could not even be

characterized as subsistence farming, if one, by referring to subsistence

farming, means a farm with some surplus production capacity that can be sold in

exchange for basic necessities (Bäcklund, 1988). Farming conditions were simply too poor, something that became

painstakingly clear during the frequent crop failures, such as the famine in

the late 1860s. Bäcklund therefore chose to label this type of agriculture subsistence small farming. Still, this form of agriculture in which grassland farming on outlying,

marginal land such as moors, was an essential support for the sparse

population. It was the expansion of the sawmill industry along the northern

Swedish coast that boosted demand for labor in the hinterland. For instance,

Nils-Gustav Lundgren has estimated that the 350,000 cubic meters annually

harvested in Jokkmokk area in Norrbotten around the turn of the century

required approximately 2,700 forestry workers (Lundgren, 1984). Owing to the

high demand for labor, there was also an increased element of wage labor. In

the 1880s, about 70% of smallholders depended on wage income, equivalent to

around 200 SEK per year, which in turn was equal to more than 100 days of

payments for an agricultural worker (Jörberg, 1972: 714). As forestry expanded and outfield farming was gradually

abandoned, it created a structural change within Norrland agriculture. Another

outcome was that more male labour in the forest required more women’s work in the agriculture (Bäcklund, 1988). In parallel, there were substantial investments in transport

networks. Streams were cleared from rocks and other obstructions to allow for

timber floating, while timber floatation on the lakes depended on steam tugs (Törnlund, 2002). The road network was expanded from the 1840s as state subsidies

were first introduced (Lassila, 1972: 151) and, as Bäcklund notes (1988: 47), the roads were absolutely essential for the expansion

of timber cutting from the 1870s. The railway reached Norrbotten in the 1890s

and along with coastal steam shipping from the 1840s and the construction of

inland roads, this provided the backbone of a distribution system partly

organized by forest companies, with the main purpose of providing fodder for

horses and food for the lumbers.

Northern Sweden held around 14% of the Swedish population in 1880, while the

output of grain and root vegetables, foremost potatoes, only accounted for 7%

of the country total (BiSOS, 1880c). The growing population in northern Sweden was therefore depending on

food transports from southern Sweden and from abroad. While the imports of

foreign grain to southern and central Sweden constituted less than 7% of the

production of grain in these parts of the country, the corresponding figure for

northern Sweden was close to 20%. Of the total Swedish meat imports in 1880,

almost 50% were destined for Norrland (BiSOS, 1880b). These transports were in turn mirroring the industrialization itself.

By 1880, the Swedish registered steamer tonnage belonging to staple towns and

private owners and intended for domestic trade was half the tonnage of sailing

ships (BiSOS, 1880a: tabs. 1, 2, 3). Norrland’s share of the sailing ship tonnage was around 7%, while Norrland’s share of steamer tonnage was 35%. This is well in line with the hypothesis

that modern technology was important for opening previously non-utilized,

organic forest resources. The railway reached southern Norrland by the late

1870’s and the north, connecting the Swedish trunk line to the Iron ore railway

between Luleå and Narvik in 1895. The role of the railways for facilitating the exploitation

of the bio-resources of the north is further exemplified by the so-called

Norrland Tariff, a railway transport subsidy in effect from 1895 to 1930 and

which mainly concerned grain freights from southern to northern Sweden

(Pettersson, 1999: 281). The tariff reflected both the southern Swedish farmers

need to find new markets, as the foreign competition had become harder during

the 1880’s, and the fact that Norrland was not self-sufficient in grain and

root-vegetables, while at the same time, both the forest industry and the

mining industry of the north needed more labour. Thomas Petterson (1999) points

out that prior to the railways, factory owners in Norrland were forced to store

foodstuffs in the autumn, before the harbors had not yet frozen over, a

solution that was both expensive and inconvenient.

The full utilization of the forest therefore depended on Sweden’s integration into the world economy and the use of coal based transportation

systems. In short, while sawn timber wasexported to the European markets, food

from southern Sweden and abroad such as American pork was distributed to the

hinterland. The role of coal was indirect as a fuel in both the transportation

networks and in the engineering industry that delivered machines to the saw

mills.

6. The charcoal consumption in the Iron Works

As previously pointed out, the charcoal consumption of the ironworks was

significant. Estimates suggest that 21 million hectoliters of charcoal was

consumed around the year 1800, equivalent to approximately 2.5 million cubic

meters of wood, which meant that the ironworks required a hinterland for the

supply of fuel and foodstuffs for the labor force. The localization pattern of

the ironworks was therefore rather diffused (Olsson, 2007). This was not only a

reflection of the area dependence of the organic energy system, but also due to

the difficulties in transporting charcoal long distances without the charcoal

shaking down into a powder. The production of charcoal was also strictly

regulated, which should be kept in mind when the role of relative prices in the

energy transformation is analyzed. To start with, there was a pre-emption obligation within the mining district (Olsson, 2007: 43). A Yeoman was obliged to first

offer the charcoal to the local iron work to a useful price. Only if they turned down the offer, it was allowed to sell charcoal outside

the mining district Bergslagen. This regulation was abolished in 1850. The

charcoal market outside Bergslagen was liberated in 1846, motivated by the

elimination of the Forging Ordinance the same year (Olsson, 2007). This means

that market prices for charcoal only came to existence from 1850.

The localization of ironworks, huts and hammers was administered by the crown,

through the Swedish Board of Mines, which set productions allowances and

conceded privileges for different parts of the iron production process. This

was both an expression of the mercantilist state and of resource management of

limited forest and hydropower assets (Olsson, 2007: 39-42). By the second half

of the 19th century, the iron industry was in a process of rationalization with extensive

closures. At the same time, however, iron production increased, implying a

concentration to larger units (Attman, 1986). The transformation pressure was

due in turn to the lower iron prices due to the increased supply of British

iron, which in turn ultimately depended on the increased production capacity

and high productivity achieved through coke-fired blast furnaces, in short

England’s transition to a mineral based energy system. The transformation of the organic

economy in Sweden could, theoretically, be the expected result if the price of

coal fell relative to fire wood and charcoal. It is, however, important to

realize that saw timber did not have an alternative use as firewood or charcoal

since the saw mill industry used larger timber dimensions as compared to the

dimensions used for fuels. First, large dimension timbers, often around 90

centimeters in diameter, were not as prone to sinking as smaller dimensions

when floated. Second, debarking a big log was more labor efficient per cubic

meter as compared to debarking a smaller log. In both cases this is due to the

geometrics of the cylinder; how surface area, which rises to the power of two,

is related to volume, which rises to the power of three. Thirdly, the saw dust

waste was relatively smaller when sawing larger logs. It is more convenient to

handle and split smaller logs, thus explaining why these dimensions were used

for charcoal and firewood. Since large and small timber were not close

substitutes, it is important to collect prices for both sawtimber and firewood.

The fuel and timber prices are shown in Figure 2.

FIGURE 2

Fuels and wood prices per MJ relative to coal. Sweden, 1866-1910

Sources: coal (Statens Järnvägar; BiSOS, 1866-1902; Kander, 2002: 1903-1910); charcoal (Olsson, 2007; based on Jörberg, 1972); wood pine (Jörberg, 1972); wood birch (Jörberg, 1972: 498ff, Skaraborg County); pulp wood (Ljungberg, 1990).

There is no reliable information on the development of coal prices in Sweden

from mid-1860, while a compilation coal prices for earlier dates have not been

made. The prices published as Swedish prices are, as shown by Fredrik Olsson

indeed series from the Danish historical national accounts, which in turn were

transformations of British export prices (Olsson 2007: 50-51). The prices from

1866 have been collected from the State Railways (Lindmark & Olsson-Spjut, 2018). Charcoal prices were approximately 5 to 15% lower per

Joule than coal prices until 1880, when charcoal became approximately 20% more

expensive than coal. This price relation lasted throughout the 1880’s and early 1890’s. This means that if coal and charcoal had been perfect substitutes, coal ought

to have replaced charcoal in the iron industry no later than 1880. Since that

was not the case, the two fuels cannot have been perfect substitutes. Also,

relative prices were relatively stable. A more pronounced relative price shift

did only occur during the period from 1894 and onwards. By the year 1900

charcoal was 50% more expensive than coal, and by 1910 charcoal was three times

as expensive. There were two reason for this. First, technical change had given

rise to an alternative use of spill wood and small timber dimensions as

pulpwood. When demand for small-sized timber increased, prices rose, which in

turn drew up the charcoal prices. Secondly, industrialization itself caused an

increased demand for labor, which caused rising wages also for the coalers.

Charcoal production was relatively labor intensive, which shifted the cost

structure especially for charcoal. The combination of the expansion of the pulp

and paper industry from especially the 1890s and more rapidly increasing wages

from the same decade explain the late switch from charcoal to coke in Swedish

blast furnaces, where the first coke fired furnace was started in 1905. In

short, it seems as if the major price-wise reason to switch to coke happened

when increased demand for small wood also made charcoal more expensive.

Simultaneously with the changeover to coke, there was also an increased

tendency of concentration in the iron industry into fewer but larger units.

This processes came to a climax during the economic crisis of the early 1920’s crisis, which virtually wiped out charcoal fired blast furnaces (Söderlund & Wretblad, 1957). The bottom-line is that coke enabled increased economies of

scale in the iron industry. The late transition to coke in Swedish iron

manufacturing may in turn be explained by the development of relative prices

for coal, firewood and labour. These changes were in turn partly the result of

the dynamics between the organic and mineral energy systems, as it was the

evolution of a wood based pulp and paper industry that propelled the final

stages of the transformation of the iron industry from charcoal to coke. First,

the pulp and paper industry’s demand for small timber resulted in rising prices for these dimensions which

altered the relative prices between coal and coke and, thereby, the cost

structure in the iron industry. At first only spruce was used for paper pulp

production, but as pine also became available for the pulp manufacturing

process, the competition over timber hardened between the paper pulp industry

and the charcoal manufacturing. Secondly, and as noticed previously, the

slender timber dimensions were inclined to sinking if floatation was attempted.

The forest industry’s cleansing of natural streams for more efficient timber floatation, investments

in coal consuming steamers, tugs and railways, made it possible to secure

supplies of raw materials to the pulp industry around the turn of the century.

Finally, while the raw material used in the pulp manufacturing process was

organic, the pulp and paper mills were highly depending on coal. In 1913, the

first year for which reliable data on the sectoral coal consumption in Sweden

exists, the pulp and paper industry accounted for around 30% of the

manufacturing industry’s total coal consumption. Coal fired steam engines were not the least used for

driving generators, providing electricity for machines. It is therefore not

surprising to learn that the pulp and paper industry’s share of the total installed engine power of the Swedish manufacturing

industry was also around 30% in 1913. The pulp and paper industry also changed

forestry itself as smaller timber dimensions became more valuable (Heckscher,

1941). First, thinning of the forests became profitable, thereby improving the

growth rate of large trees intended for saw timber. Secondly, a shorter

turn-around time meant that less capital was sunk in growing forests. This

improved the profitability of forest companies and probably facilitated the

emergence of sustainable forestry and practices that stood in sharp contrast to

the 19th century forest tycoons, often associated with illegal logging, land grabbing,

unethical business methods and deforestation (Gaunitz, 1990).

At this stage we are inclined to draw some tentative conclusions if we first can

explain why the use of coal increased dramatically, in presence of an absolute

price disadvantage in terms of cost per energy unit over firewood, while there

were no dramatic changes in relative prices between biofuels (firewood and

charcoal) and coal until the turn of the century. Price data shows that coal

was at all occasions more expensive than pine wood, while slightly less

expensive than birch wood.

The difference in price level can be explained if coal and charcoal were not

perfect substitutes in every respect. As previously argued this was clearly the

case concerning steam engines and especially so steam engines requiring a high

boiler capacity, such as locomotives. Thus, we can conclude that the increased

demand for coal was primarily derived from the demand for mechanical power

provided by steam engines in the manufacturing industry and transport sectors.

This explains why the coal consumption increased despite coal being more

expensive than pine firewood in terms of energy and despite the fact that coal

prices in comparison to biofuels remained fairly stable. In order to explain

why the relative prices were stable we need to conclude that coal and firewood

were close substitutes in low-end uses, such as residential heating. Coal had

an edge over firewood, but only in cities with houses equipped with central

heating and major coal imports for industrial uses and gas works (Lindmark & Andersson, 2010). Firewood therefore remained an important domestic fuel well

after the period studied here.

7. Hydropower

Hydropower was an important organic energy source which also was part of the

dynamics between the organic and mineral energy systems. This transformation

rested on two basic innovations, the turbine and alternating current

technologies. The first wave of saw mill expansion was based on mechanical

hydropower using water wheels. During the early stages of Swedish

industrialization, mechanical hydropower was essential for both the expanding

saw mill industry and had since long been of great strategical importance for

the iron industry. Gösta Eriksson even suggested that the demand for additional hydropower

contributed to the spatial diffusion of the iron industry during the 19th century (Eriksson, 1955). Indeed the total effect of mechanical hydropower in

the manufacturing industry and mining was larger than that of steam power as

late as 1900 (BiSOS, 1900a, 1900b). The official statistics reports approximately 250,000 HP in

mechanical hydropower and 174,000 HP in steam engines. Hydropower therefore

substituted for coal during the Swedish industrialization, even if it is

difficult to estimate the importance in terms of energy flows, as mechanical

hydropower usually did not admit continuous operation throughout the year. The

first turbines came to Sweden from Switzerland and France in the early 1840s’s and domestic production commenced a few years later with flour and saw mills

as the main customers (Spade, 2008: 35-6). From 1893 hydropower was again

transformed through the emergence of electrical engineering and alternating

current technologies. This time Sweden jumped on the bandwagon as one of the

leading nations. At the turn of the century, around 13% of the mechanical water

power was used for driving generators (BiSOS, 1900b). The considerable difference between industries regarding the use of

hydropowered generators is an indicator of the structural transformation of the

second industrial revolution. The new industries that represented the 20th century economy were often based on the use of electricity. More than 90% of the

mechanical hydropower in the chemical industry was used for driving generators.

And concerning electrical generators, the chemical industry was dominated by

chlorate and calcium carbide manufacturing. Chlorate was used in the match and

explosives industries, both emerging industries. Calcium carbide was used in

the manufacturing of acetylene gas, which in turn was used in carbide lamps, as

a welding gas and for purifying steel from sulfur. The transformation of

hydropower from mechanical to electrical hydropower was therefore also part of

a co-evolutionary process between the organic and mineral energy systems.

8. Conclusions

The Swedish industrialization was characterized by the co-evolution of the

organic and mineral energy systems. The saw mill industry was depending on the

establishment of transportation systems bringing in food stuffs for laborers

and loggers in the north and for transporting timber and sawn products to the

coast and foreign markets. Thus, the raw materials utilized were products of

the organic energy system, while the transport system was a mix of technologies

of the organic system, such as sailing ships and streaming rivers, and

technologies of the mineral system, including steamers, tugs and railways. The

diffusion of the mineral energy system was strongly associated with the

mechanization of the manufacturing industry and transports sectors where

firewood and coal were not as close substitutes as one could imagine. We

therefore propose that demand for coal was mainly derived from the demand for

steam powered machines while pure substitution effects, coal substituting for

firewood, were less important during the 19th century. The evolution of the wood based pulp and paper industry during the

late 19th century exemplifies the dynamics of the co-evolution of the organic and mineral

energy systems. As the pulp industry increased the demand for small timber,

prices rose for these dimensions which made firewood and charcoal more

expensive relative to other fuels. This contributed to the shift from charcoal

to coke in the iron industry but also changed the economic situation in

forestry as forest management became more profitable. Finally, also hydropower

was part of the change. Mechanical hydropower had been an important factor of

production with regard to the iron industry and, from the mid-19th century, the saw mill industry. With the emergence of electricity, hydropower

came to form the center of new clusters of industry and innovation for the 20th century. The Swedish example demonstrates how the dynamics of energy transitions

unfold in several dimensions, geographical, technological, economical,

entrepreneurial and institutional, and that these dimensions are often

interconnected. It is important to consider that aggregated analyses, focusing

on easily quantified dimensions such as the composition of energy carriers,

total energy growth and relative prices, may obscure how energy transformations

are linked to the general economic history of specific countries.

ACKNOWLEDGEMENTS

The authors would like to thank the anonymous reviewers for their valuable

comments and suggestions to improve the quality of the paper. The research was

supported by Stiftelsen Riksbankens Jubileumsfond through the project “The limits to growth in a sustainable society: Energy use and area requirements

in early modern Sweden” (Dnr P10-0701:1) and Jan Wallanders och Tom Hedelius Stiftelse samt Tore

Browaldhs Stiftelse “Engines for sustainability. Horsepower prices, capital sub- stitution and energy

transitions in the long run”.

REFERENCES

Allen, R. C. (2009). The British Industrial Revolution in Global Perspective. Cambridge: Cambridge University Press.

Attman, A. (1986). Svenskt järn och stål 1800-1914. Stockholm: Jernkontoret. (Jernkontorets bergshistoriska skriftserie, 21).

Bäcklund, D. (1988). I industrisamhällets utkant: Småbrukens omvandling i Lappmarken 1870-1970. Doctoral dissertation. Umeå: Umeå Universitet.

BiSOS (1866-1902). Statens järnvägar (L). Stockholm: Statistics Sweden.

Bunte, R., Gaunitz, S. & Borgegård, L. E. (1982). Vindeln: En norrländsk kommuns ekonomiska utveckling 1800-1980: En analys av bondesamhällets ekonomiska utveckling, anpassning och förvandling under 200 år. Lund: Degerfors.

Eriksson, G. A. (1955). Bruksdöden i Bergslagen efter 1850: Med särskild hänsyn till företag i Kolbäcksåns dalgång. Stockholm: Jernkontoret. (Jernkontorets Bergshistoriska Skriftserie, 15).

Gadd, C. J. (2000). Det svenska jordbrukets historia. 3: Den agrara revolutionen 1700-1870. Stockholm: Natur och Kultur.

Gales, B., Kander, A., Malanima, P. & Rubio, M. (2007). North versus South: Energy Transition and Energy Intensity in Europe

over 200 Years. European Review of Economic History, 11(2), 219-253.

Gaunitz, S. (1980). Baggböleriet-om konsten att avverka norrlandsskogarna utan att bryta för mycket mot lagen. Västerbotten, (1), 2-14.

Harrison, D. (2002). Jarlens sekel: En berättelse om 1200-talets Sverige. Stockholm: Ordfront.

Heckscher, E. F. (1941). Svenskt arbete och liv: Från medeltiden till nutid. Stockholm: Bonnier.

Jonsson, K. (2001). Järnhanteringen i norra Västergötland: Arkeologiska undersökningar i Essunga, Främmestad, Istrum, Ledsjö, Lerdala, Vättlösa och Älgerås socknar. Stockholm: Jernkontoret. (Jernkontorets Bergshistoriska Utskott, 71).

Jörberg, L. (1972). A History of Prices in Sweden 1732-1914. 1: Sources, Methods, Tables. Lund: Gleerup.

Kander, A. (2002). Economic Growth, Energy Consumption and CO2 Emissions in Sweden 1800-2000. Doctoral dissertation. Stockholm: Almqvist & Wiksell. (Lund Studies in Economic History, 19).

Kander, A., Malanima, P. & Warde, P. (2013). Power to the People: Energy in Europe over the Last Five Centuries. Princeton: Princeton University Press.

Krantz, O. & Schön, L. (2007). Swedish Historical National Accounts 1800-2000. Stockholm: Almqvist & Wiksell. (Lund Studies in Economic History, 41).

Lassila, M. (1972). Vägarna inom Västerbottens län: Kommunikationernas utveckling mot bakgrund av befolkning och näringsliv. Umeå: Umeå Universitet.

Lindmark, M. & Andersson, L. F. (2010). Household Firewood Consumption in Sweden during the Nineteenth Century. Journal of Northern Studies, (2), 55-78.

Lindmark, M. & Olsson-Spjut, F. (2018). From Organic to Fossil and In-Between: New Estimates of Energy

Consumption in the Swedish Manufacturing Industry during 1800-1913. Scandinavian Economic History Review, 66 (1), 18-33.

Lindmark, M. & Minde, K. B. (2018) Et energiregnskap for Fastlands-Norge 1835-2012/Energy Consumption in

the Norwegian Mainland Economy 1835-2012. Heimen, 55 (2), 157-177.

Lindqvist, S. (1984). Technology on Trial: The Introduction of Steam Power Technology into Sweden,

1715-1736. Uppsala/Stockholm: Uppsala Universitet/Alqvist & Wiksell. (Uppsala studies in history of science, 1).

Linnaeus, C. (1960 [1732]). Carl von Linnés lappländska resa: Caroli Linnæi Iter Lapponicum. Stockholm: Natur och Kultur.

Ljungberg, J. (1990). Priser och marknadskrafter i Sverige 1885-1969: En prishistorisk studie. Doctoral thesis. Lund: Ekonomisk-historiska fören. (Skrifter utgivna av Ekonomisk-historiska föreningen, 64).

Lundgren, N. G. (1984). Skog för export: Skogsarbete, teknik och försörjning i Lule älvdal 1870-1970. Doctoral dissertation. Umeå: Umeå Universitet. (Umeå studies in Economic History, 6).

Myrdal, J. (Ed.) (1999). Det svenska jordbrukets historia. 2: Jordbruket under feodalismen: 1000-1700. Stockholm: Natur och kultur.

Norberg, P. (1958). Forna tiders järnbruk i Norr- och Västerbotten. Stockholm: Almqvist & Wiksell.

Olsson, F. (2007). Järnhanteringens dynamik: Produktion, lokalisering och agglomerationer i

Bergslagen och Mellansverige 1368-1910. Doctoral dissertation. Umeå: Umeå Universitet. (Umeå studies in Economic History, 35).

Pettersson, T. (1999). Institutional Rigidity and Economic Change: A Comparison between

Swedish Transport Subsidies. In L. Andersson-Skog & O. Krantz (Eds.), Institutions in the Transport and Communications Industries: State and Private

Actors in the Making of Institutional Patterns, 1850-1999 (pp. 199-215). Canton: Science History Publications.

Pomeranz, K. (2000). The Great Divergence: China, Europe, and the Making of the Modern World Economy. Princeton: Princeton University Press.

Sieferle, R. P. (2001). The Subterranean Forest: Energy Systems and the Industrial Revolution. Cambridge: The White Horse Press,

Söderlund, E. & Wretblad, P. E. (1957). Fagerstabrukens historia. 3: Nittonhundratalet. Uppsala: Almqvist & Wiksell.

Sörlin, S. (1988). Framtidslandet: Debatten om Norrland och naturresurserna under det

industriella genombrottet. Stockholm: Carlssons.

Spade, B. (2008). En historia om kraftmaskiner. Stockholm: Riksantikvarieämbetet.

Sundström, A. (2009). Samuel Owen: Teknik- och ångbåtspionjär. In Dædalus: Tekniska museets årsbok. Vol. 77. Stockholm: Tekniska museet.

Sverige Kommerskollegium (1880a). Bidrag till Sveriges officiella statistik (BiSOS). E) Inrikes och sjöfart handel. Stockholm: L. J. Hjerta.

Sverige Kommerskollegium (1880b). Bidrag till Sveriges officiella statistik (BiSOS). F) Utrikes handel och sjöfart. Stockholm: L. J. Hjerta.

Sverige Kommerskollegium (1880c). Bidrag till Sveriges officiella statistik (BiSOS). N) Jordbruk och boskapsskötsel. Stockholm: L. J. Hjerta.

Sverige Kommerskollegium (1900a). Bidrag till Sveriges officiella statistik (BiSOS). C) Bergshandteringen. Stockholm: L. J. Hjerta.

Sverige Kommerskollegium (1900b). Bidrag till Sveriges officiella statistik (BiSOS). D) Fabriker och handtverk. Stockholm: L. J. Hjerta.

Törnlund, E. (2002). “Flottningen dör aldrig”: Bäckflottningens avveckling efter Ume- och Vindelälven 1945-70. Doctoral dissertation. Umeå: Umeå Universitet. (Studies in Economic History, 27).

Wilkinson, R. G. (1988). The English Industrial Revolution. In D. Worster (Ed.), The Ends of the Earth: Perspectives on Modern Environmental History. Cambridge: Cambridge University Press.

Wrigley, E. A. (1962). The Supply of Raw Materials in the Industrial Revolution. The Economic History Review, 15 (1), 1-16.

Wrigley, E. A. (1988). Continuity, Chance and Change: The Character of the Industrial Revolution in

England. Cambridge: Cambridge University Press.

Wrigley, E. A. (2010). Energy and the English Industrial Revolution. Cambridge: Cambridge University Press.

Wrigley, E. A. (2016). The Path to Sustained Growth: England’s Transition from an Organic Economy to an Industrial Revolution. Cambridge: Cambridge University Press.

NOTAS A PIE DE PÁGINA / FOOTNOTES